KASCCO Profile

Download PDFManufacturing success comes down to people and processes. We combine industry-trained labor with a secure, auditable management platform so you can increase throughput, reduce idle time, and stay fully compliant with Saudi regulations. Whether you run food lines, packaging plants, or materials processing, our teams are trained, documented and ready to integrate with your operations.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

Trusted by Manufacturing Leaders

Buscuit

City Cement Company

PepsiCo

Andalus

Mama Sauce

King Salman Park

Tanmiah

MBCC

What We Do for Industry

How It Works

Assessment & Plan

We map your lines, takt times and skill needs.

Onboard & Train

Document checks, HSE induction and role-specific training.

Deploy & Integrate

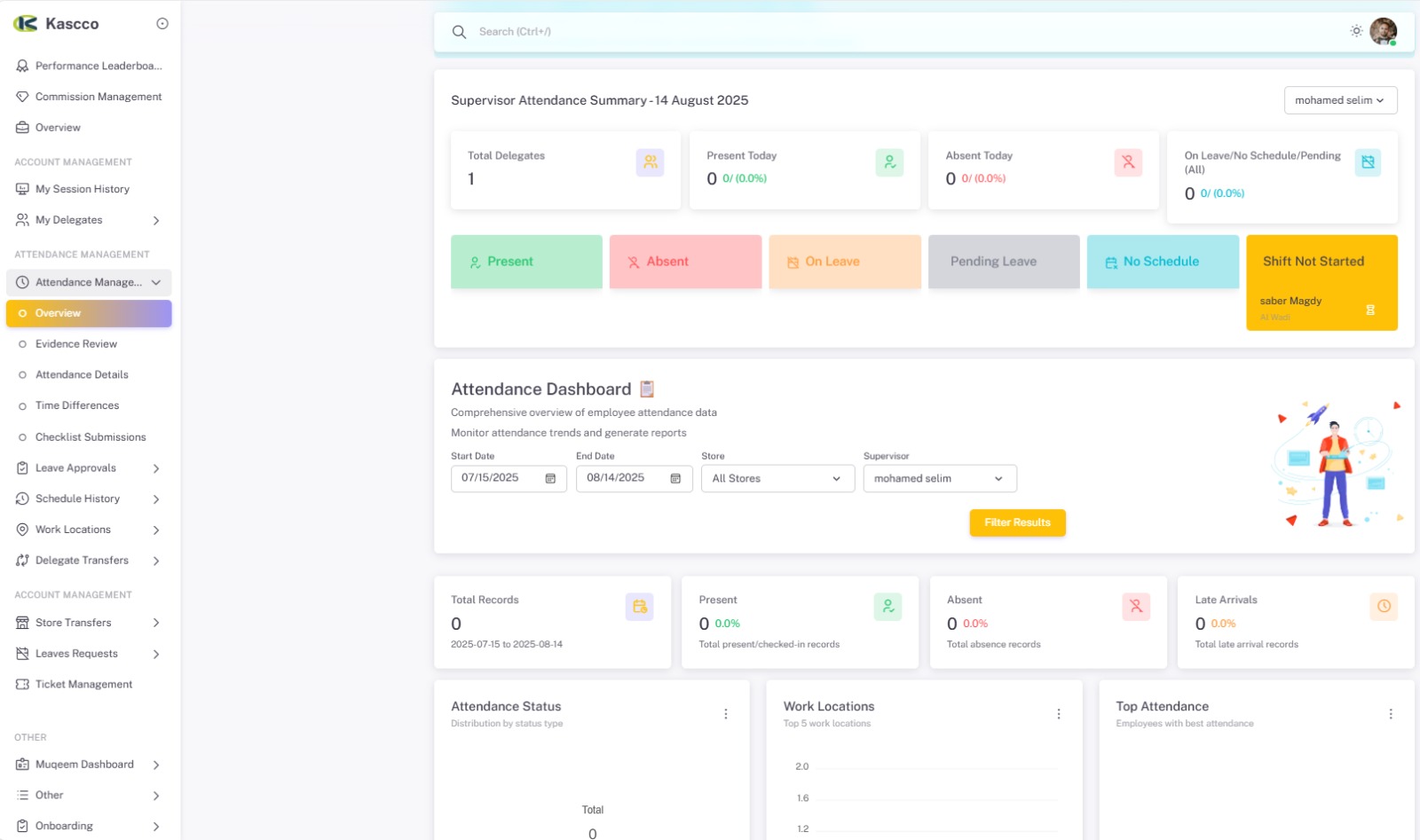

Workers arrive with mobile app access; attendance and tasks start immediately.

Optimize & Scale

Monthly reports, continuous improvement workshops, and scaling strategy.

Frequently Asked Questions

How do you ensure production quality when using temporary staff?

Each worker passes role-specific training and a pre-shift QC checklist. Supervisors and QC inspectors monitor real-time metrics — non-conforming outputs trigger immediate corrective workflows.

Can we integrate your platform with our ERP or MES?

Yes — we provide API-based integrations and exportable reports to sync attendance, payroll and production KPIs with your ERP/MES.

What reporting cadence do we get?

Daily shift reports, weekly executive summaries, and a customizable monthly analytics package.

"Their team provided the right mix of process discipline and local talent. The reporting made bottlenecks visible and helped us improve OEE across the plant."— Head of Operations, Food Manufacturing Group